Propellant Stimulation

– Create fractures up to 35 ft in every perforation tunnel

– Replace acid or improve the effectiveness of acidizing

– Replace or improve small to medium size frac jobs

– Minimize vertical migration out of zone

GasGun propellant enhanced stimulation technology is designed and proven to lower total cost of operations and improve the profitability of open and cased hole producing and injection wells.

How GasGun Works

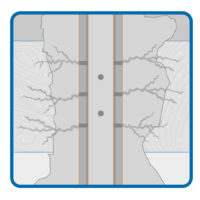

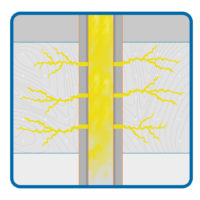

Progressively burning GasGun propellant generates high-pressure gas which creates fractures that extend deep into the formation to improve productivity or injectivity. Engineers who analyze GasGun’s effectiveness by initial production or injection (IP/II) increase, operating time and safety will observe that the return on incremental investment in enhanced well performance routinely exceeds their expectations. Workover programs that standardize GasGun have allowed some operators to eliminate costly stimulation jobs.

Field Proven

In many applications, GasGun propellant stimulation technology has been proven to deliver distinct advantages over other stimulation methods. Enhanced Energetics offers analysis of well performance improvement when the GasGun is used to enhance or replace acid and frac jobs. Performance can also be compared with propellant technology offered by other oilfield service providers to demonstrate the increased effectiveness and power of GasGun technology.

Software Simulation

Operators and wireline service companies can benefit from proprietary modeling software that analyzes wellbore configuration, rock properties (Poisson’s ratio, Young’s modulus, fracture toughness, tensile strength, etc.), state of stress (pore pressure, overburden stress, horizontal stresses, etc.) and concentration stress around the wellbore. Post-frac test data can be used to develop proprietary stimulation models that create competitive advantage for enhancing well performance with our patented propellant technology.

– Gun size: 1.563, 2, 3.375, or 4.0 inches (40, 51, 86, or 102 mm)

– Creates multiple radial fractures into the formation and up to 35 feet from the wellbore.

– Available in diameters that can accommodate 2 7/8” tubing/casing and larger.

– Wireline and tubing-conveyed systems available for both vertical and horizontal well.

– Reusable high strength steel carrier and subs.

– Arming procedures comply with API RP-67.

– Maximum pressure: 8,000 psi (55 MPa)

– 1-hour/10 hour temperature rating: 280 F [138 C] / 260 F [127 C]*

*Exceeding maximum temperature ratings can result in unintentional detonation

-A minimum tubing size of 2.875″ is required for clearance with the use of the 2″ OD GasGun system. A minimum casing size of 4.5” or a 3.875” open hole is required for clearance with the use of the 3.375″ GasGun carrier. A minimum casing size of 7” or a 6” open hole is required for clearance with the use of the 4″ carrier.

-Maximum 1-hour temperature rating is 280 F (138 C). Maximum 10-hour temperature rating is 260 F (127 C). **Warning: Exceeding the maximum temperature ratings can result in unintentional detonation.**

-A minimum fluid column of 300 feet (100m) is recommended. An optimal level is 1000 feet (300m) or more.

-Maintain a minimum 100-foot air cushion between the top of the fluid and the wellhead.

-The fluid column can be anything compatible with the formation such as fresh water, brine, KCL water, oil, diesel, and most acids.

-In cased hole wells, perforation density of 6 shots per foot with a 0.375″ entry hole diameter or larger is a recommended minimum for the 3.375″ and 4″ OD GasGun systems. Larger entry holes are preferred over deep penetration.

-A perforation density of 6 shots per foot with a 0.25″ entry hole or larger is the recommended minimum for the 1-9/16″ and 2″ GasGun systems.

-Minimum distance from PBTD is 15 feet

-Minimum distance of 80 feet between a GasGun and a packer.

-If there is a bridge plug in the well it is recommended that there be at least 20 feet of cement on top of it.

-In open-hole wells no perforations are required.

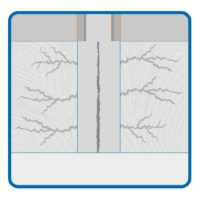

GasGun® stimulation bypasses nearbore damage and

GasGun® stimulation bypasses nearbore damage and

dramatically increases perforation hole depth.

Download: Wolfbone

Operator successfully completes Travis Peak Well with GasGun® Fracturing Tool

Operator successfully completes Travis Peak Well with GasGun® Fracturing Tool

Download: Travis Peak Well

This technical paper was prepared by Medco LLC, Oman and is a detailed case study on the use of the GasGun in four injection wells and one producing well in a south Oman sandstone reservoir. Download: Medco Case Study (Oman)

This technical paper was prepared by Medco LLC, Oman and is a detailed case study on the use of the GasGun in four injection wells and one producing well in a south Oman sandstone reservoir. Download: Medco Case Study (Oman)

Look at these results obtained by a major Canadian producer who compared the GasGun against their frac treatments. Download: GasGun vs. 5 Tonne Sand Frac

Look at these results obtained by a major Canadian producer who compared the GasGun against their frac treatments. Download: GasGun vs. 5 Tonne Sand Frac

Check out the case study article published in the September 2001 issue of World Oil.

Check out the case study article published in the September 2001 issue of World Oil.

Download: World Oil Article

Take a moment to review some case studies from Kansas published in the North Midcontinent PTTC.

Take a moment to review some case studies from Kansas published in the North Midcontinent PTTC.

Download: PTTC Article

Enhanced Energetics propellant is ignited inside perforated pipe. The first explosion is the blasting cap and detonating cord. The following rush of gas coming out of the holes is the propellant burn. The entire event takes ~2 seconds, but in a well the burn takes only ~20 milliseconds due to higher confining pressures. The rate of gas coming out of the holes continually increases until the burn is complete. This is due to the progressive burning properties of our propellant.

This is an animation of a well stimulation performed with the use of a GasGun propellant stimulation tool. In this example, the GasGun tool is conveyed into the well on wireline, but it can also be run on conventional tubing or coil tubing.

This video is from a downhole camera used before and after a GasGun stimulation. The stimulation was conducted in a shallow Berea sandstone well located in Ashland County, Ohio. The well was an open hole completion which makes it possible to observe the multiple fractures created by the GasGun.

Enhanced Energetics’ propellant tools can eliminate near wellbore damage and improve well performance. This slotted liner’s restriction to flow resulted in a non-productive well and poor field economics. With a simple wireline intervention you can improve production and increase the value of your assets.

Safety

Use of Enhanced Energetics equipment contrary to manufacturer’s specifications or operating instructions may result in property damage, serious injury or fatality. If you are not trained in the handling and use of explosive devices, do not attempt to use or assemble any GasGun or Kraken systems. Explosives are destructive by nature. Do not attempt to disassemble or alter explosive products in any manner. Do not crush, hammer, pinch, impact, pull wires or abuse any explosive product.

Be sure to follow safe operating practices as found in API RP-67 in accordance with governmental regulations, company policies and manufacturer’s recommendations.

GasGun cartridges, carriers, subs, etc. are designed, developed, tested and manufactured by Enhanced Energetics. Components such as blasting caps, detonating cord, etc. integrated with the GasGun system must be approved Enhanced Energetics prior to use. Failure to follow this warning along with the well preparation and fielding guidelines could result in damage to the carrier and/or downhole equipment